Carbon Fiber wet layup PART 2 YouTube

Fast and Free Shipping On Many Items You Love On eBay. Looking For carbon fibr? We Have Almost Everything On eBay.

FS Wet Lay Carbon Fiber Fender w/ Vents North American Motoring

What is Wet Carbon Fiber? Wet carbon fiber, also known as wet-lay carbon fiber, refers to the manufacturing process where carbon fiber fabric is impregnated with a liquid epoxy resin. This resin is then cured or hardened to create a rigid and durable composite material.

Carbon fiber layup Bercella

The terms "dry" and "wet" in carbon fiber refer to how the product is produced or manufactured. Each has its own unique approach, but the result is actually quite different in terms of weight, strength and other factors. Dry carbon fiber is crafted with pre-preg or impregnated resin fibers that are already in the carbon itself.

How to make DIY carbon fiber parts at home with wet lay YouTube

What is Wet Carbon Fiber? Wet carbon fiber is the carbon fiber that has that overall glossy finish to it that you might see on a high end Mercedes, for example. Generally cheaper than dry carbon fiber, wet carbon fiber can be produced mainly in one of two ways: painting or infusion.

DIY Carbon Fiber Wet Lay/Overlay Pt. 4Peoples Choice YouTube

We needed a right angle for the bracket shape, and rather than make a mold, we put 18-gauge steel in the metal brake and finished the bend over a table edge. We mounted our metal to keep it from.

Wet Layup Vacuum Bagging Cored Carbon Fiber Panel YouTube

Wet carbon fiber, also known as "wet-lay" carbon fiber, is the traditional method of creating carbon fiber components. In this process, carbon fiber fabric is saturated with liquid epoxy resin, which is then allowed to cure. The wet-lay method involves layering the fabric by hand onto a mold, ensuring each layer is fully impregnated.

Carbon Fiber StepbyStep How to Lay Up Carbon Fiber Hot Rod Hot

Wet layup is used for building and repairing boats, and making composite parts. In this article, we'll describe the types of resin and reinforcement fabrics, explain how to calculate the materials you'll need, and provide steps for completing a project using the wet layup method. READ ABOUT IT Wet Layup Overview Choosing a Resin for Wet Layup

My home made wet lay carbon fibre heal guard for my 2010 BMW R1200 GS

Wet Layup In this method, carbon fibers are laid onto a mold, wetted with resin, and rolled or squeegeed to remove excess resin. The layup can be left open or a vacuum bag applied. It is then cured under room temperature or with heat and pressure to create a carbon fiber composite part.

How To Hand Lay Carbon Fiber YouTube

Many studies that were performed to assess the longevity of wet-layup carbon fiber reinforced polymer (CFRP) composites confirmed their excellent durability properties [84, 96]. These studies.

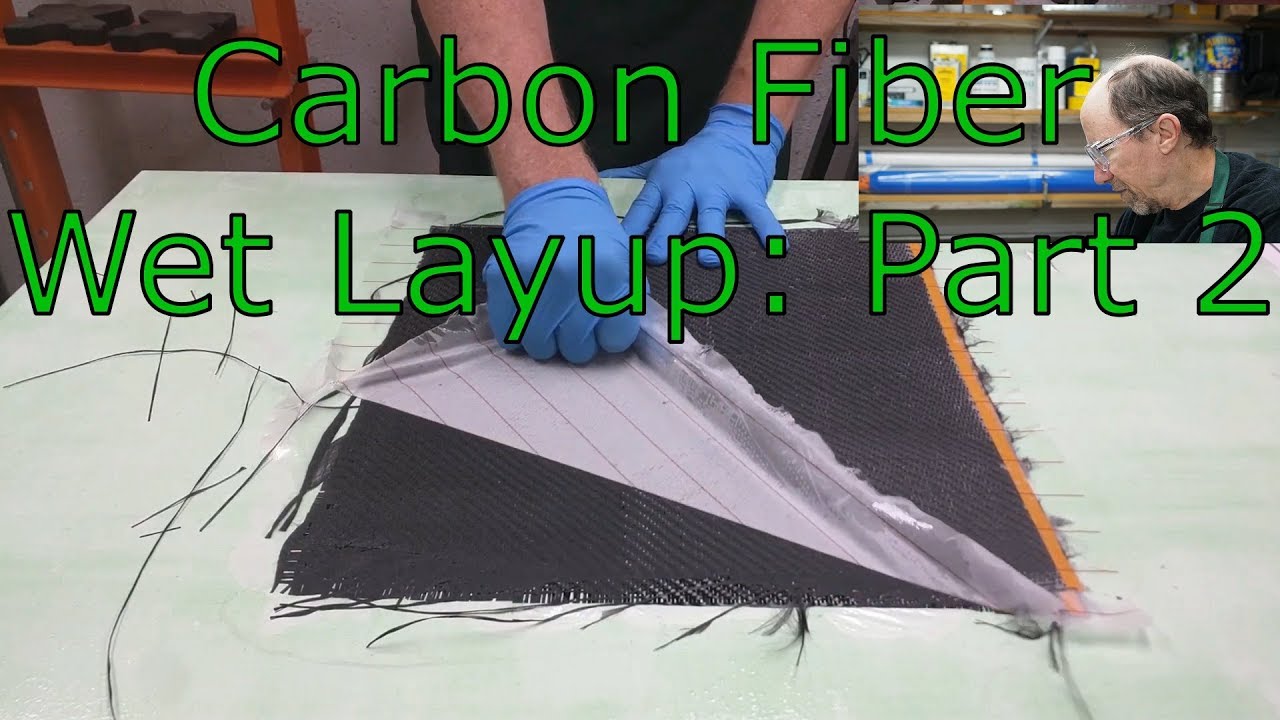

Carbon Fiber Wet Layup Part 2 YouTube

Continuation of relearning the composite wet layup process after 20 years. This part 2 covers mixing epoxy, wet layup, curing, removing peel ply and trimming.

What are the Fundamental Steps of Composites Manufacturing?

Step 4: Sizing. Prior to weaving, the carbon fibers must be sized, or coated, with a polymer to protect them during the weaving process. The sizing is selected for compatibility with the laminating resin to be used. The fibers are then wound onto bobbins, spun, and processed into various weaves and other formats.

DIY Carbon Fiber Wet Lay/Overlay Pt 6Peoples Choice YouTube

How to Make a Carbon Fiber Panel- Wet Lay Technique AJ Hartman Aero 26K subscribers Subscribe Subscribed 3.9K Share 127K views 2 years ago Carbon Fiber and Composites Scissors:.

How to Make a Carbon Fiber Panel Wet Lay Technique YouTube

Fostering best practices for wet layup procedures As fabricators continue to manufacture composite tools and parts using an open mold, wet layup process — often with mixed success — it's important to stress proper preparation, materials, application methods and standardization. Carbon Fibers Materials Glass Fibers Processes Reinforcements Infusion

FS Wet Lay Carbon Fiber Fender w/ Vents North American Motoring

Typical fibre volume (and weight) fractions for wet layup (based on the fibre type and form) are shown in Table 3.1. Here, we assume \(V_\text {f}\approx 0.4\): a mid-range value typical for wet layup of unidirectional composites. Four layers (plies) of carbon fibre are stacked and orientated in the same direction to create a UD FRC of.

Wet laying carbon fibre 2x2 cloth and chopped style carbon

Advantages of carbon fiber Carbon Fiber Molding Techniques Wet Lay-Up Prepreg Lamination Resin transfer molding (RTM) 3D Printing for Creating Molds Using 3D printing for carbon fiber mold manufacturing Benefits of 3D printed molds Other Carbon Fiber Manufacturing Methods Autoclave Curing Bladder Molding Compression Molding Cast Molding

DIY Carbon Fiber Wet Lay/Overlay Pt. 5Peoples Choice YouTube

In wet lay-up manufacturing, sheets of carbon fiber are cut and pressed into a mold, then painted with a liquid resin, which, as it cures and solidifies, binds the sheets into the desired final shape. This method requires the least equipment and is also the easiest to master as a beginner.